Monitoring of multi-service vehicles in the Line 15 South Section T3A Tunnel

project

As part of the Grand Paris Express project, the construction of the line 15 South tunnel is divided into several sctions.

The one named T3A, 4.2 kilometres long, links the Pont de Sèvres to the Fort d’issy – Vanves – Clamart station.

Challenge

The tunnel construction represents millions of euros, and each day of delay significantly increases the overall budget. Controlling the schedule and optimising operations are keychallenges.

In a tunnel project such as T3A, logistics can account for up to 30% of the production issues. If the supply of segments is not optimised, the site cannot progress at the planned rate. The segment logistics are managed by the multi-service vehicles (MSV), so the client wanted to analyse the work sequences of MSV in order to improve their productivity.

The project goals were:

- Mesure Multi-service vehicles usage rate

- View the position of the MSV from the supervision cockpit

- Measure the average journey time

- Identify areas of abnormal stoppages

Start of project : 2021

UBY solution

We connected 3kms of tunnel and 3 MSVs with a mesh network (a wireless, autonomous system with an accuracy of 5m).

Our platform of worksite productivity has integreted the tunnel plan to locate the MSVs in real time and to visualise the loading / unloading area.

We provided also a dashboard with KPIs as :

- MSV utilization rate

- Activity sequences and time by activity

- Identification of abnormal downtime

Benefits

Optimization of MSV allocation

Our references

- UBY Productivity

Horizon Grand Paris: Line 15 South – T3A Tunnel

- UBY Productivity

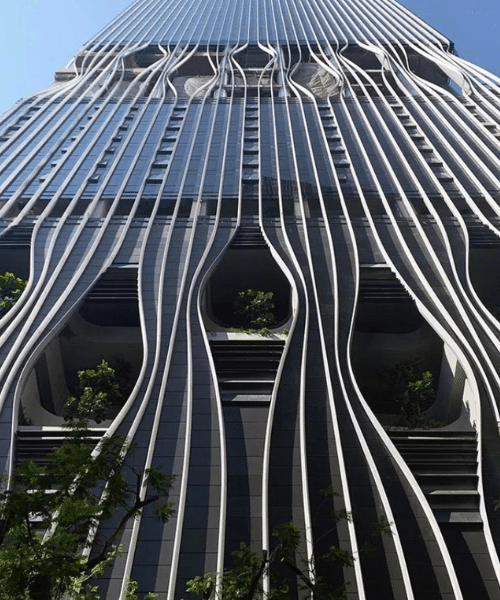

Dragages Singapore: Glory Tower – Singapore

- UBY Productivity

Bouygues Travaux Publics: Extension of LRT1 light rail line

- UBY Productivity